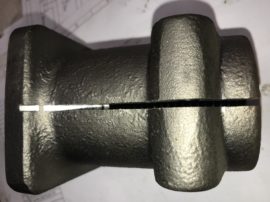

Quality control of mechanical parts in China

Mechanical parts quality in China – When putting in place partnerships with factories, the first criteria for KIREX TECHNO is the high consideration the management has for quality, and the investment made in that area within the plant.

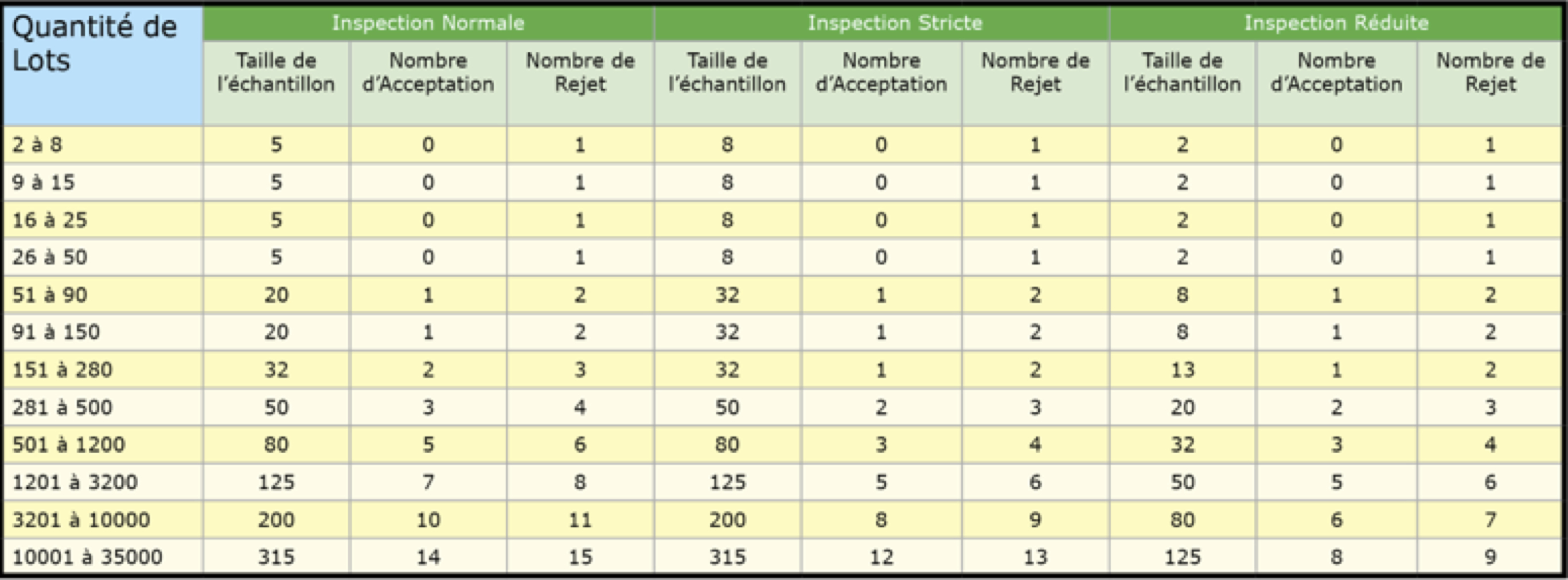

All of our factory partners are fully equipped with a complete range of quality control tools. This includes standard basic inspection equipment to high-end specific equipment. Not only are these equipment functional, but the technicians are extensively formed to use these tools, and to follow a quality control protocol.

For all our projects, an engineer from KIREX TECHNO personally puts in place the control forms and procedures for each references. This procedure is put in place during the project pre-study and the manufacturing of the samples. It is constantly updated all along the production life of the reference, in order to prevent any non-conformity, and to reach 100% quality targets.

The technicians at our factory are informed and trained for each procedure, and the final inspection are always done by a KIREX TECHNO engineer.

For more precision on the equipment we have at hand, please check out the QUALITY CONTROL sections of each of OUR AREAS OF EXPERTISE.