Lost wax casting process, known also as investment casting process, enables to manufacture parts with particularly good surface roughness and precise dimensional tolerance.

Process quick description

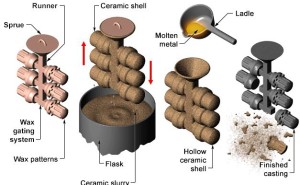

An intermediary model is generated with a mould, usually made of steel or aluminium, that is injected with wax. The wax pattern once cooled will represent the shape of the part to be manufacture, with slightly larger dimensions to take it into account the shrinkage of molten metal.

Wax patterns are assembled to form a tree with a gating system which allows to optimize the production of several parts at once. Up to 7 layers of refractory materials are applied on the wax surface. Those layers form the shell from which the wax is removed, by melting it, and in which molten metal is finally cast. The elimination of the wax through heating leaves only the refractory shell representing the negative shape of the form to cast.

Two types of wax and shells

Several types of wax and refractory shell can be used. KIREX TECHNO Precision Casting at Ningbo, China, masters the two most common types:

1. SSLW: Sodium Silicate Lost Wax

That process allows to cast various shapes of relatively large parts (1 to up tp 150kg) in all common alloy steel: low alloyed to special high strength requirements high alloyed steel. It results in good mechanical properties and inner quality. Accurate dimensional tolerances and a good surface aspect makes it a very largely used manufacturing process for sub-components used in construction machinery , lifting systems, mining, train machinery, forest machinery, an so on.

2. CLW: Ceramic Lost Wax

The shell refractory is made out of Zircon ceramic, and the green colour wax usually employed is subject to very little deformation. The process is more costly, involving special protected atmosphere, and allows to reach higher rough-cast precision tolerances and a better surface. It is mainly used to cast small dimensions (max 20kg) and is well suited for high alloyed steel, chrome-nickel, stainless steel. It is adapted for applications with stringent surface quality requirements and dimensional precisions such as: aeronautical parts, medical devices, architectural components, specific tools, etc.

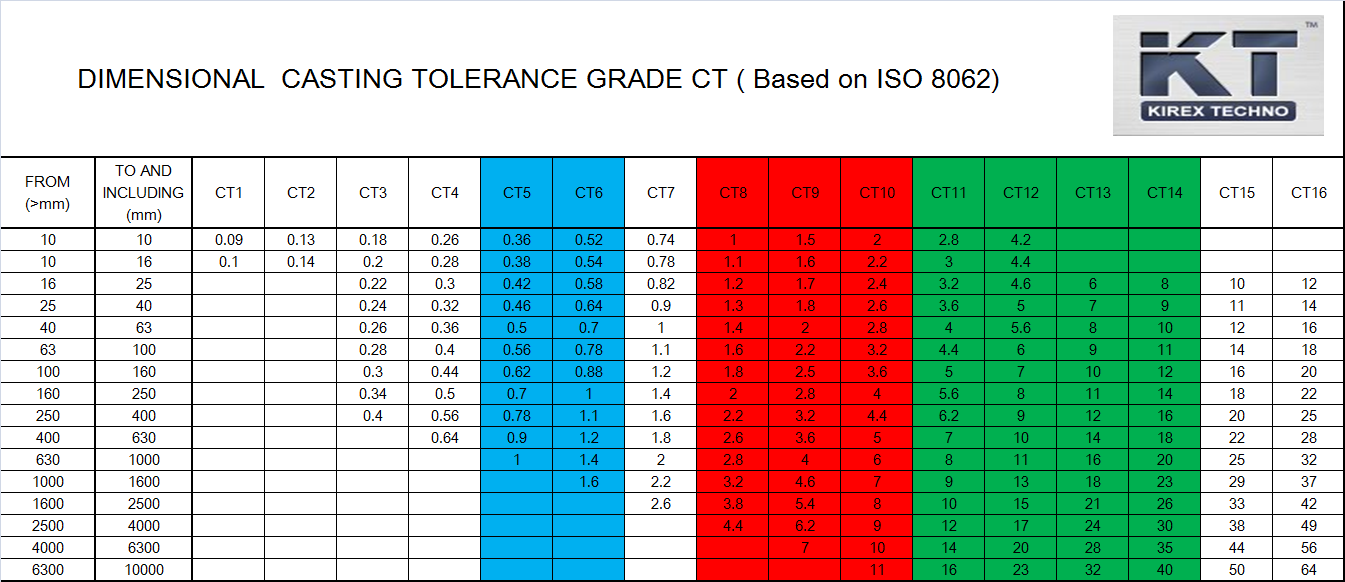

The dimensional table hereunder sums-up the tolerance grade of 3 casting process:

- SSLW lost wax,

- CLW lost wax and

- sand casting

Blue : Lost wax casting (ceramic) – Ra: up to 3.2

Red: Lost wax casting (sodium silicate) – Ra: from 8 to 10

Green: Sand casting – Ra: 12.6

For more information and indications for choosing the most suited process for your parts, do not hesitate to contact us.